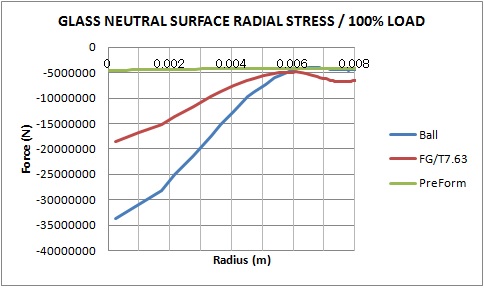

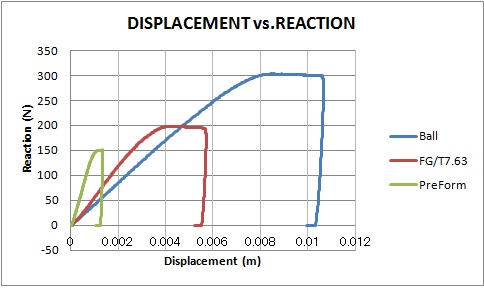

In the glass molding process, optical properties of glass lens is under

the strong effect of the initial shape of glass material and the loading

history.

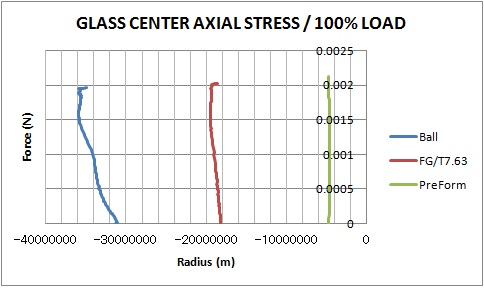

In the central part of press mold, axial force(normal force) is predominant,

whereas in the part, frictional force(tangential force) is predominant.

And, as the angle between the press moving direction and mold surface

comes closer to 0(zero), inprint quality becomes lower.

In this case, the effect of optimization of mold shape and unloading

process on the product quality, is shown including the effect of visco-

elastic characteristics of glass material, comparing the following

3(three) cases of initial shape :

(1) Pure sphere

(2) Oval sphere

(3) Concave preform